Content Menu

>> Redefining the Modern Apparel Manufacturer With AI and Digital Design

>> Accelerating Product Creation With AI Enabled Design

>> Predictive Analytics Improves Forecasting and Production Planning

>> Strengthening Quality and Reducing Waste With Digital Prototyping

>> How Lever Style Uses AI and Digital Design in Daily Operations

>>> Using 3D Tools to Reduce Physical Samples

>>> Clear Digital Handover to Factories

>>> Making Production More Predictable

>>> Supporting Faster Response to Change

>> Improving Material Efficiency With AI Driven Sustainability

>> Advantages for Brands That Adopt Early

>> Creating a More Agile, Digitally Enabled Apparel Industry

>> Contact Us

![]() Redefining the Modern Apparel Manufacturer With AI and Digital Design

Redefining the Modern Apparel Manufacturer With AI and Digital Design

Apparel manufacturing is changing as brands shift more of their design and development work into digital tools. AI and 3D technology are no longer optional. They help teams work faster, reduce errors, and communicate more clearly.

This shift is not about replacing people or reinventing the entire workflow. It is about solving practical problems. According to the State of Fashion 2026 report by McKinsey, 35 percent of fashion executives already use generative AI in areas like product discovery and image creation (page 33). Adoption is growing, but most companies are still in early stages.

For manufacturers, the goal is simple: use digital tools to make development smoother, sampling lighter, and production more predictable.

![]() Accelerating Product Creation With AI Enabled Design

Accelerating Product Creation With AI Enabled Design

Traditional development often requires several rounds of physical samples, long waits, and repeated adjustments. Digital design reduces this load.

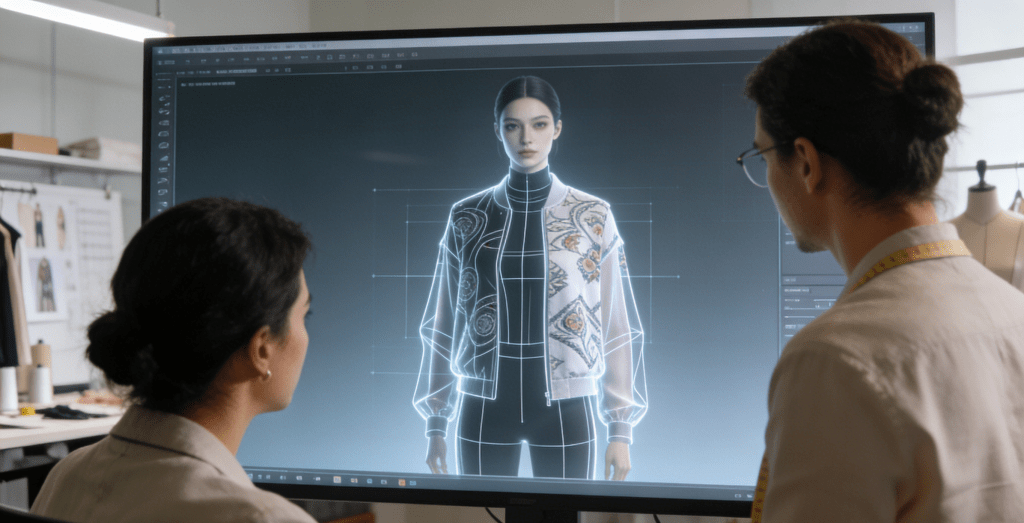

3D tools allow teams to see style lines, proportions, and construction details before producing anything physical. This helps designers and manufacturers align earlier, which cuts unnecessary sampling and reduces delays.

AI assisted pattern tools can also highlight fit concerns or construction issues before they reach the factory floor. The State of Fashion 2026 report notes that Tapestry has started using digital twins to reduce the number of early physical samples (page 85). This is a clear example of how virtual reviews can replace work that once required fabric, trims, and shipping.

For premium brands with busy calendars, these time savings matter. A faster digital review means fewer last minute changes, which protects cost and quality.

![]() Predictive Analytics Improves Forecasting and Production Planning

Predictive Analytics Improves Forecasting and Production Planning

Forecasting demand has always been difficult for apparel companies. Seasons shift, sell through varies by channel, and trends move quickly. Predictive analytics helps bring more structure to planning.

By combining past sales, market trends, and channel behavior, brands can estimate volumes with better confidence. Manufacturers benefit as well, because they receive earlier visibility on expected capacity needs.

AI driven planning tools can also identify possible delays or bottlenecks, allowing teams to adjust before schedules are impacted. This does not guarantee perfect forecasting, but it reduces guesswork and improves communication between brands and factories.

![]() Strengthening Quality and Reducing Waste With Digital Prototyping

Strengthening Quality and Reducing Waste With Digital Prototyping

Quality is one of the biggest priorities in premium apparel. Digital prototyping supports this by allowing teams to test drape, fit, and construction virtually.

Instead of discovering issues after cutting fabric, many can be identified earlier in the digital stage. This reduces the number of physical prototypes and lowers material waste.

Digital prototyping is especially helpful for categories with complex construction, such as outerwear, luxury RTW, and technical activewear. It creates a more consistent standard across different factories and regions.

![]() How Lever Style Uses AI and Digital Design in Daily Operations

How Lever Style Uses AI and Digital Design in Daily Operations

At Lever Style, AI and digital tools are part of our everyday work. We focus on using them in simple, practical ways that help brands move faster and avoid unnecessary problems.

![]() Using 3D Tools to Reduce Physical Samples

Using 3D Tools to Reduce Physical Samples

We use Style3D as part of our development workflow. Our teams build 3D styles so clients can review fit, silhouette, and details earlier in the process. For many programs, this reduces the number of physical samples needed and shortens the development cycle.

This helps especially in categories like activewear, outerwear, knits, and soft wovens, where physical prototypes normally take time and effort.

![]() Clear Digital Handover to Factories

Clear Digital Handover to Factories

Because we work with multiple factories across Asia, we prepare digital handover packs that include 3D files, technical notes, construction guidelines, and visual references. This reduces misunderstandings, improves quality consistency, and speeds up onboarding when programs move between factories.

![]() Making Production More Predictable

Making Production More Predictable

Digital design makes early decisions clearer. When details are confirmed earlier, factories can plan capacity with fewer changes later. This reduces the risk of delays and helps protect delivery timelines.

![]() Supporting Faster Response to Change

Supporting Faster Response to Change

Our asset light model allows us to move production between partner factories when needed. Because our development process is digital, these transitions are easier and require fewer new samples. This flexibility helps brands manage demand shifts, duty changes, and logistical challenges.

![]() Improving Material Efficiency With AI Driven Sustainability

Improving Material Efficiency With AI Driven Sustainability

AI and digital design reduce physical sampling and limit unnecessary shipments. Marker optimization tools increase fabric efficiency, and forecasting tools help reduce overproduction.

These improvements support sustainability goals without slowing down development or adding cost.

![]() Advantages for Brands That Adopt Early

Advantages for Brands That Adopt Early

The benefits of early adoption show up in everyday operations. Teams that use digital design tools make decisions sooner, lock specifications earlier, and reduce rework. Predictive planning helps brands and factories prepare more accurately.

The State of Fashion 2026 report notes that digitisation can unlock 8 to 12 percent reductions in sourcing costs (page 86), and AI enabled PLM to ERP integration can produce double digit cost savings by improving planning and visibility (page 85).

These outcomes depend on the quality of the underlying workflow, but they show the real potential of digital tools when used properly.

![]() Creating a More Agile, Digitally Enabled Apparel Industry

Creating a More Agile, Digitally Enabled Apparel Industry

AI and digital design are becoming standard components of modern apparel manufacturing. They do not replace craftsmanship or creativity. Instead, they make the process clearer, faster, and more resilient in a global environment where product cycles are shorter and risk is higher.

Brands that adopt these tools early build stronger, more flexible supply chains and improve development workflow across categories.

![]() Contact Us

Contact Us

If you want to bring more speed, accuracy, and clarity into your development and production process, our team can help. Contact us to learn how we support premium brands with a flexible, digitally enabled manufacturing platform.

Fantastic resource. Do you offer a PDF version of this post?

This was a pleasant surprise — high-quality content and useful tips.

. thank you